Advantage Sintered Metals

Mining & Metals, 5701 W Dickman Rd Ste A, Battle Creek, Michigan, 49037, United States, 51-200 Employees

Phone Number: 26********

Phone Number: 26********

Who is ADVANTAGE SINTERED METALS

ASM is a manufacturer of powdered metal components for the Automotive, Outdoor Power, Medical, Furniture, Industrial and Appliance Industries. Pressing capabilities from 12 to 750 ton, wh...

Read More

-

Headquarters: 5701 W Dickman Rd Ste A, Battle Creek, Michigan, 49037, United States

-

Date Founded: 1991

-

Employees: 51-200

-

Revenue: $10 Million to $25 Million

-

Active Tech Stack: See technologies

Industry: Mining & Metals

SIC Code: 3399

|

NAICS Code: 332999 |

Show More

Does something look wrong? Fix it. | View contact records from ADVANTAGE SINTERED METALS

Advantage Sintered Metals Org Chart and Mapping

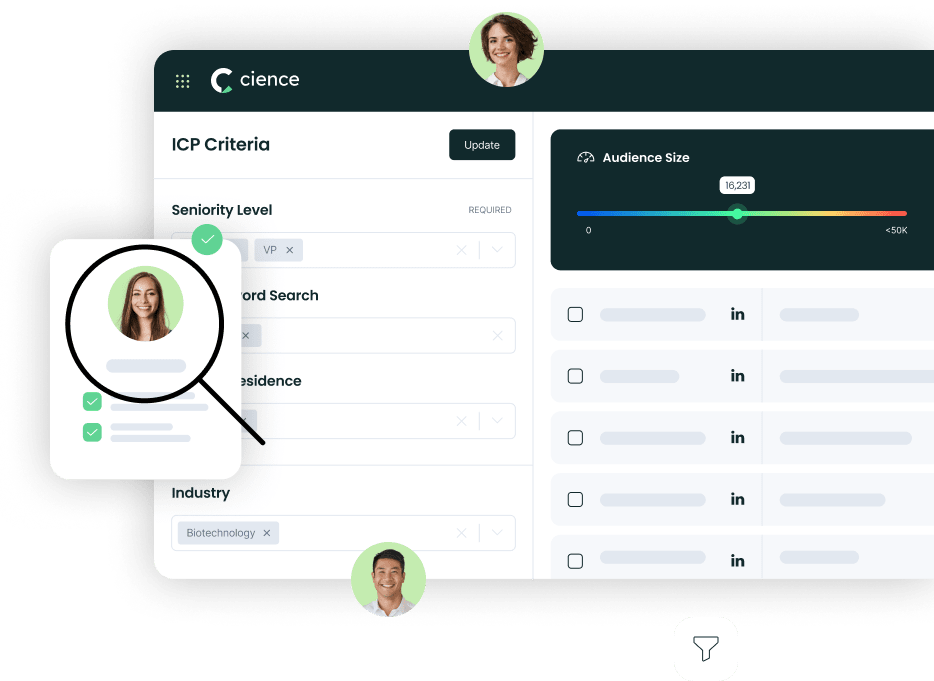

Sign in to CIENCE GO Data to uncover contact details

Free credits every month

Frequently Asked Questions Regarding Advantage Sintered Metals

Answer: Advantage Sintered Metals's headquarters are located at 5701 W Dickman Rd Ste A, Battle Creek, Michigan, 49037, United States

Answer: Advantage Sintered Metals's phone number is 26********

Answer: Advantage Sintered Metals's official website is https://advantagesintered.com

Answer: Advantage Sintered Metals's revenue is $10 Million to $25 Million

Answer: Advantage Sintered Metals's SIC: 3399

Answer: Advantage Sintered Metals's NAICS: 332999

Answer: Advantage Sintered Metals has 51-200 employees

Answer: Advantage Sintered Metals is in Mining & Metals

Answer: Advantage Sintered Metals contact info: Phone number: 26******** Website: https://advantagesintered.com

Answer: ASM is a manufacturer of powdered metal components for the Automotive, Outdoor Power, Medical, Furniture, Industrial and Appliance Industries. Pressing capabilities from 12 to 750 ton, which allows for a large variation in part size. We provide parts with both ferrous and non-ferrous materials. Our capabilities include the following secondary processes: CNC machining, coining, ball sizing, steam treat, coatings and resin impregnation. ASM has extensive capabilities to provide complex assemblies. For more information contact us via LinkedIn or visit our website.

Premium Sales Data for Prospecting

-

Sales data across over 200M records

-

Up-to-date records (less decayed data)

-

Accurate Email Lists (real-world tested)

-

Powerful search engine and intuitive interface

Sign in to CIENCE GO Data to uncover contact details

Free credits every month