C&H Plastics, Inc

Plastics, 145 Conger Avenue, Waterville, New York, 13480, United States, 1-10 Employees

Phone Number: +17*********

Phone Number: +17*********

Who is C&H PLASTICS, INC

Quality plastic parts from design, tooling, and prototype to manufacture, assembly, and packaging…ISO Registered and UL Certified. C & H Plastics, Inc. uses injection molding to produc...

Read More

-

Headquarters: 145 Conger Avenue, Waterville, New York, 13480, United States

-

Date Founded: 1970

-

Employees: 1-10

-

Revenue: $250 Million to $500 Million

-

Active Tech Stack: See technologies

Does something look wrong? Fix it. | View contact records from C&H PLASTICS, INC

C&H Plastics, Inc Org Chart and Mapping

Sign in to CIENCE GO Data to uncover contact details

Free credits every month

Frequently Asked Questions Regarding C&H Plastics, Inc

Answer: C&H Plastics, Inc's headquarters are located at 145 Conger Avenue, Waterville, New York, 13480, United States

Answer: C&H Plastics, Inc's phone number is +17*********

Answer: C&H Plastics, Inc's official website is https://chplastics.com

Answer: C&H Plastics, Inc's revenue is $250 Million to $500 Million

Answer: C&H Plastics, Inc's SIC: 3089

Answer: C&H Plastics, Inc's NAICS: 326199

Answer: C&H Plastics, Inc has 1-10 employees

Answer: C&H Plastics, Inc is in Plastics

Answer: C&H Plastics, Inc contact info: Phone number: +17********* Website: https://chplastics.com

Answer: Quality plastic parts from design, tooling, and prototype to manufacture, assembly, and packaging…ISO Registered and UL Certified. C & H Plastics, Inc. uses injection molding to produce quality plastic parts. Injection molding is a manufacturing process that feeds melted thermoplastic polymer into a precision-machined steel or aluminum mold. We can mold a wide range of part sizes, as our injection molding machines range from a 33 Ton 3 oz. to an 800 Ton 100 oz. From our clean, modern manufacturing facility in Central New York, we process a wide variety of thermoplastic resins. They include filled and unfilled commodity and engineering resins such as polyolefins, polystyrene, nylon, vinyl, polypropylene, polyethylene, polycarbonate, PVC, PEI, ABS, PPO, and acrylics. We also mold structural foam parts and we can over-mold thermoplastic rubber on more rigid materials such as flashlights, tool grips, etc. From part design and tool engineering through molding, finishing, and packaging, we create your part with complete traceability. We manufacture quality plastic parts for customers in the medical equipment, electronics, construction/architectural, transportation, rail, and sports industries.

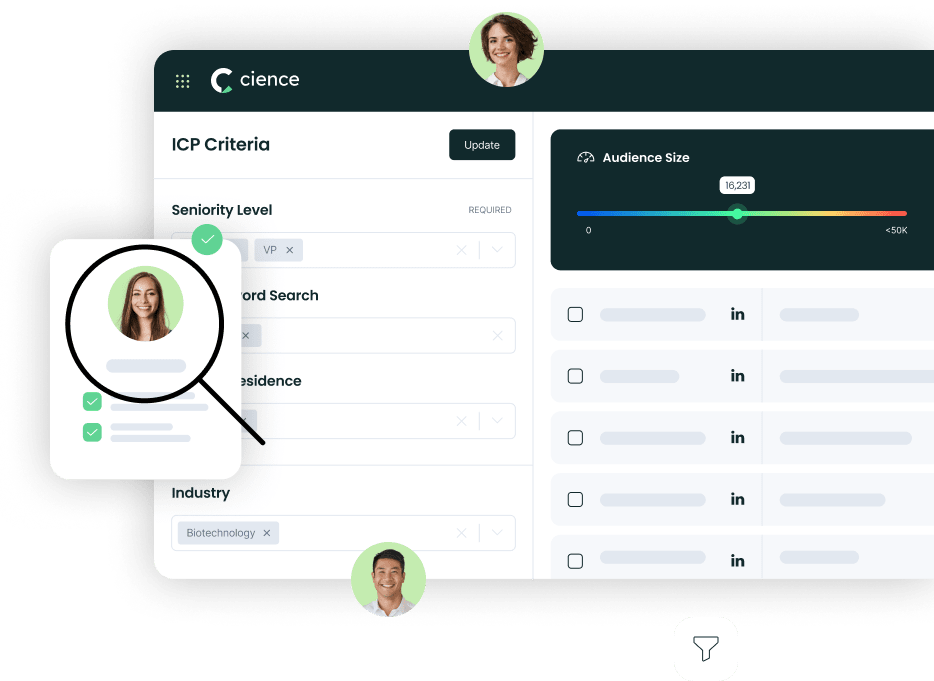

Premium Sales Data for Prospecting

-

Sales data across over 200M records

-

Up-to-date records (less decayed data)

-

Accurate Email Lists (real-world tested)

-

Powerful search engine and intuitive interface

Sign in to CIENCE GO Data to uncover contact details

Free credits every month